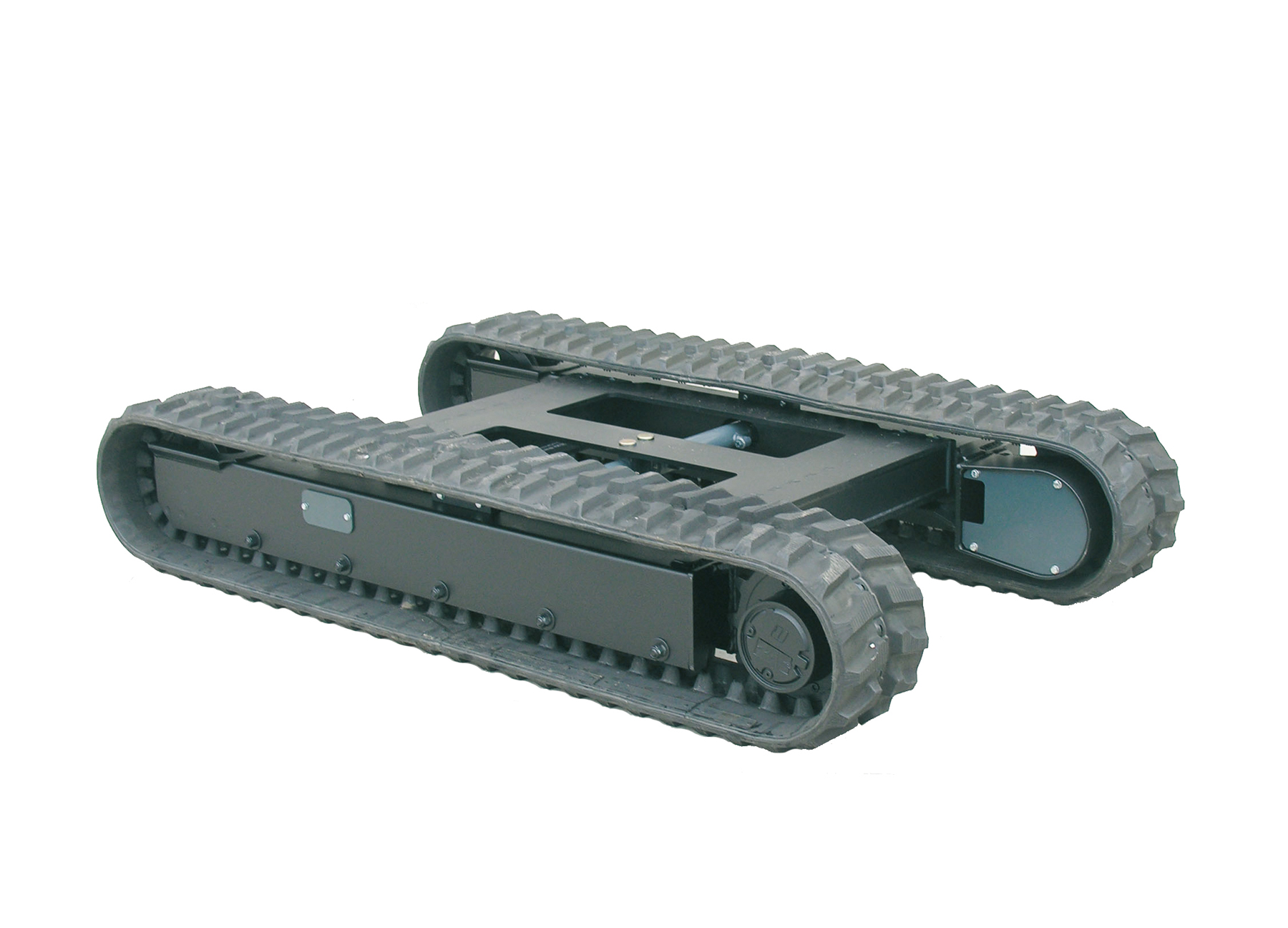

Rubber tracks

The undercarriage with low ground pressure

Hinowa has produced an undercarriage with rubber tracks to install on a variety of machines where wheels cannot be used. This technology provides an alternative form of travel, achieving low ground pressure.

Why choose this type of undercarriage?

The main goal of the company is to guaranteed a high-quality standard for all its customers. To pursue this result, the Hinowa team develops and produces top-quality undercarriages with rubber tracks, using materials and components with outstanding characteristics which guarantee benefits such as those outlined below:

- High reliability and durability

- Travel over ground which would otherwise be inaccessible to the machinery

What kind of machines can it be used on?

To meet the demands of professional operators working in different industries, the models produced by Hinowa are undercarriages with rubber tracks suitable for a large number of machines. The sectors in which they are most widely used are the industrial and agricultural sectors. More specifically, they can be installed on the following types of machines:

Industrial sector

- Machines for drilling or geological surveys

- Aerial platforms

- Cranes

- Transporters

Agricultural sector

- Harvesters

- Shredders

- Composting machines

What kind of professional figures it is suited to?

Hinowa has been in the business of producing this kind of product for over thirty years and during its history, it has developed tracked undercarriages for agricultural or various types of industrial machinery manufacturers. Furthermore, using these undercarriages has enabled companies to boost the performance of the numerous machines they manufacture.

-

- Features:

-

CONVENTIONAL RUBBER TRACKS

Model A B C D E MAX TOTAL WEIGHT (COMPLETE MACCHINE INCLUDED UNDERCARRIAGE) mm EXCAVATOR/DUMPER TRANSPORTER WITH STABILIZERS

AERIAL PLATFORMS/CRANEkg kg kg PT4G 1086 800 680 150 324 600 600 850 PT9CG 1165 865 780 180 300 850 1200 1400 PT9G 1230 930 780 180 300 950 1300 1700 PT10G 1225 860 880 200 360 1200 1400 1700 PT15G 1420 1070 980 230 360 1500 1800 2000 PT20G 1760 1390 1100 250 370 2000 2300 3000 PT20GL 1935 1570 1100 250 370 2000 2300 3000

INTERCHANGEABLE RUBBER TRACKS

Model A B C D E MAX TOTAL WEIGHT

(COMPLETE MACCHINE INCLUDED UNDERCARRIAGE)mm EXCAVATOR/DUMPER TRANSPORTER WITH STABILIZERS

AERIAL PLATFORMS/CRANEkg kg kg PT10G 1235 879 880 200 370 1200 1800 2200 PT15G 1429 1070 980 230 368 1800 2100 3000 PT1500G 1765 1407 1100 230 376 1800 2100 2400 PT20G 1765 1407 1100 230 360 2000 2300 3000 PT20GL 1955 1577 1100 230 368 2000 2300 2800 PT2000G 1727 1307 1100 230 430 2000 2300 3000 PT2500G 1830 1367 1220 250 494 2500 2800 4500 PT3000G 1985 1511 1520 300 505 3000 3500 6000 PT3000GL 2541 2067 1520 300 505 3000 3500 6000 PT4000G 2111 1637 1660 350 494 3500 3500 6500 PT70G35 2210 1699 1700 400 550 5000 5500 9000 PT70G39 2499 1988 1700 400 550 5000 5500 9000 PT70G43 2790 2280 1700 400 550 5000 5500 9000 PT100RG 3000 2404 2400 450 638 7000 9000 13000

Some models are designed for forklift handling: